Wet Screed

Traditional wet screeds - such as anhydrite or cement-based - are poured onto uneven floors and levelled across the entire surface. This is commonly prepared on site by mixing sand and cement which can be labour intensive. Nowadays, there is no shortage of ready mixed screeds to choose from, and these can be poured manually or machined.

However, for all the benefits of using wet screed, there is no way of fighting the long drying times. The British Standards recommend drying times of 1 day per mm for the first 40 mm of screed and 2 days per mm over 40 mm. For a standard 75 mm depth screed, this can mean a drying time of 110 days in even perfect conditions!

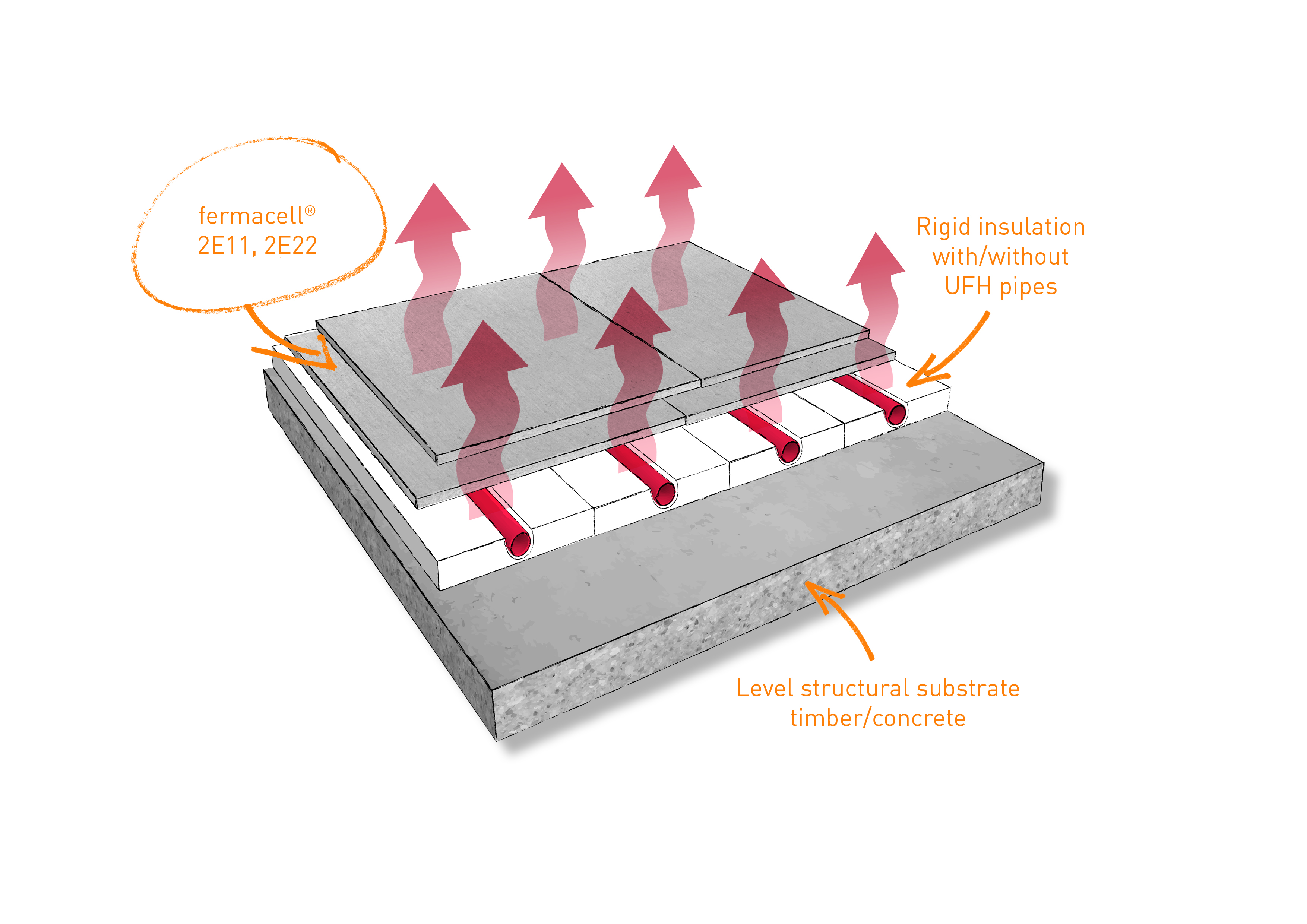

fermacell® overlay solution

Underfloor heating systems with fermacell

® boards allow for massive time savings. The fermacell

® dry screed element has a low thermal resistance value allowing heat to travel through the board easily. This make up allows for greater heat efficiency as the pipes are located directly across and under the entire floor surface, which means there is better temperature control and rapid response times.

Why use a wet screed to level a floor when dry screed options are available? Find out more here.

Why use a wet screed to level a floor when dry screed options are available? Find out more here.